services

servizi

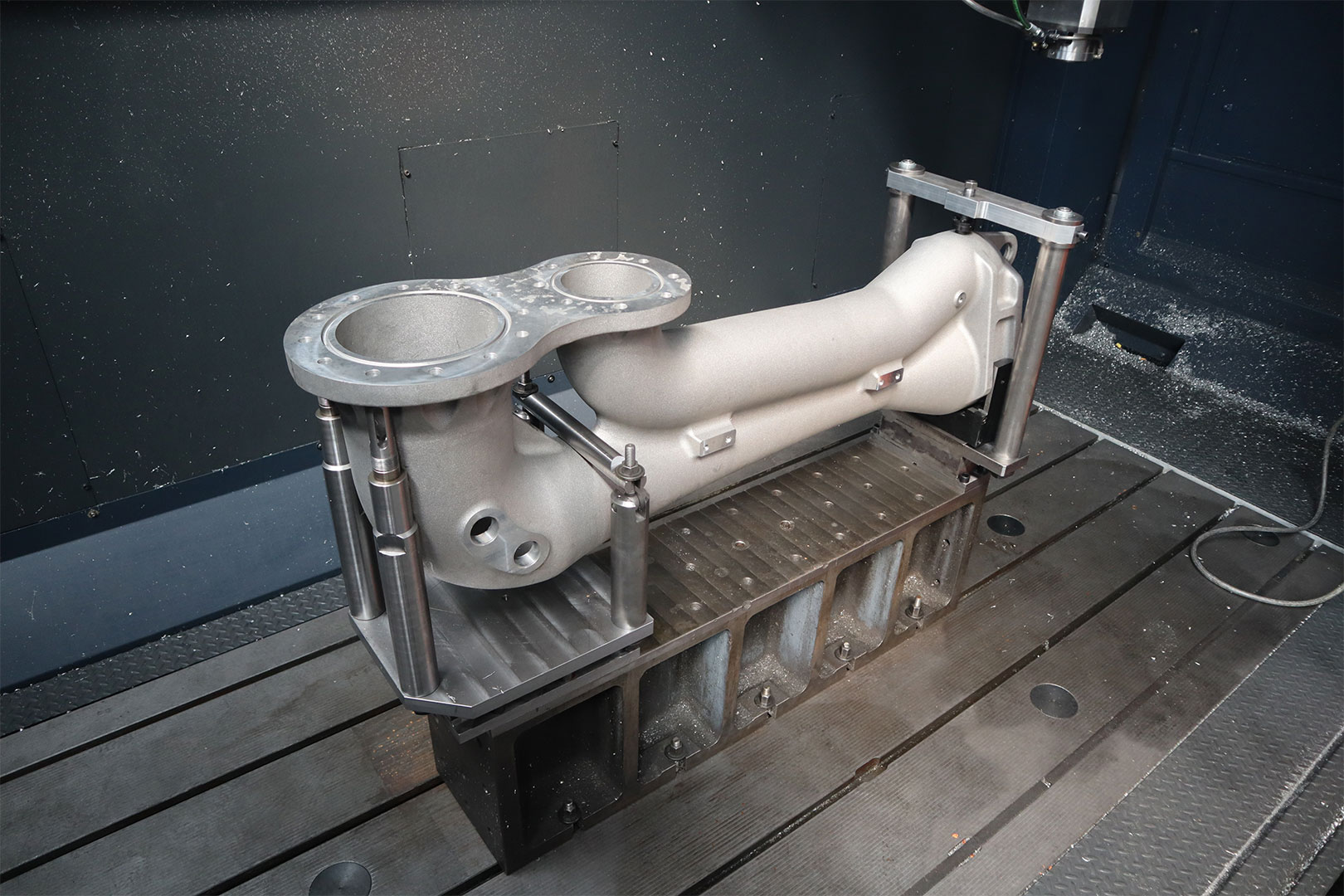

CO-ENGINEERING

Reliability, competence, efficiency.

OLM ensures professional expertise.

Customers are offered expert advice and assistance in the design process, with regard to technical aspects as well as regulatory issues.

The first step is a preliminary analysis of the product concept and its technical requirements. This is followed by an overall assessment of the production stages, in order to optimize the manufacturing process and to ensure the end product’s efficiency. OLM is able to do so while staying competitive in the market.

OLM manufactures test benches, as well: it looks after the installation and all the mechanical and electronic aspects.

Testing Area

OLM has paid attention to and improved the testing procedures since 2019. This is the reason why it has heavily invested in equipment and measuring instruments over the years.

The testing area is mainly designed to certify the manufacturing process, thanks to video recording and viewing of the outcome, by the ISO9001 regulations. A second testing area is to supervise the production in progress, checking and testing through certified instrumentation.

REFERENCES

The success and the high professionalism OLM has achieved is witnessed by the calibre of the customers that chose and keep on choosing OLM.